Come aumentare l'efficienza della produzione di soffitti metallici con l'automazione?

2024-11-22 11:59

KINGREAL CEILING MACHINERY offre un supporto clienti completo, che include l'installazione delle attrezzature, la formazione tecnica, la manutenzione e l'assistenza post-vendita. L'azienda fornisce inoltre soluzioni personalizzate per soddisfare specifiche esigenze produttive in base alle richieste del cliente.

L'automazione gestisce processi complessi come l'alimentazione dei materiali, il taglio, la perforazione e la formatura, con un intervento umano minimo. Questo riduce gli errori, abbassa i costi di manodopera e migliora la sicurezza, rendendo la produzione più efficiente e affidabile.Perché la precisione è importante nella produzione dei pannelli del controsoffitto?La precisione garantisce che i pannelli del controsoffitto soddisfino le specifiche esatte, riducendo i difetti e migliorando la qualità del prodotto. Inoltre, riduce al minimo gli sprechi di materiale e favorisce la produzione di prodotti di alta qualità in linea con le aspettative dei clienti.

Quali fattori dovrebbero considerare i produttori quando scelgono apparecchiature automatizzate per controsoffitti metallici?

I produttori dovrebbero considerare le proprie esigenze produttive, inclusi tipi e quantità di piastrelle, prestazioni delle attrezzature, assistenza e rapporto costi-benefici. Anche la modularità e l'adattabilità alle esigenze future sono fattori cruciali.

Precise Control for Higher Product Quality

Traditional ceiling tile machines that rely on manual operation are prone to inaccuracies and errors. Automated systems, on the other hand, can ensure precision at every stage of the process. For instance, the metal ceiling production line offered by KINGREAL CEILING MACHINERY is equipped with advanced numerical control systems. From cutting and perforating to bending and shaping, these systems guarantee minimal errors, ensuring that every ceiling tile meets the client's specifications.

High-quality production not only reduces the defect rate but also minimizes material waste, which is essential for cost efficiency. Additionally, superior product quality enhances a company’s market competitiveness, earning greater trust from customers.

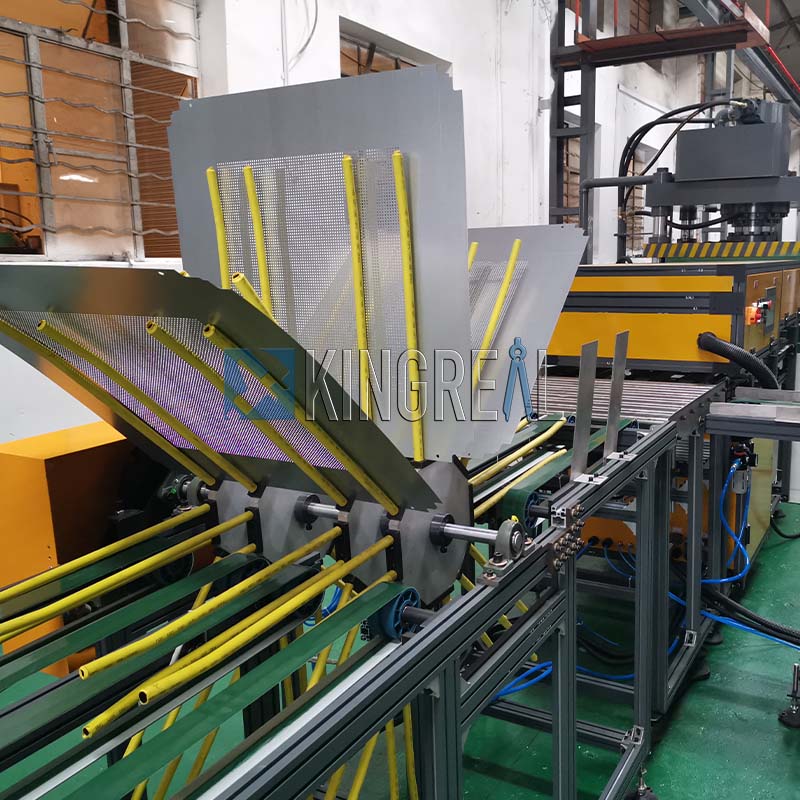

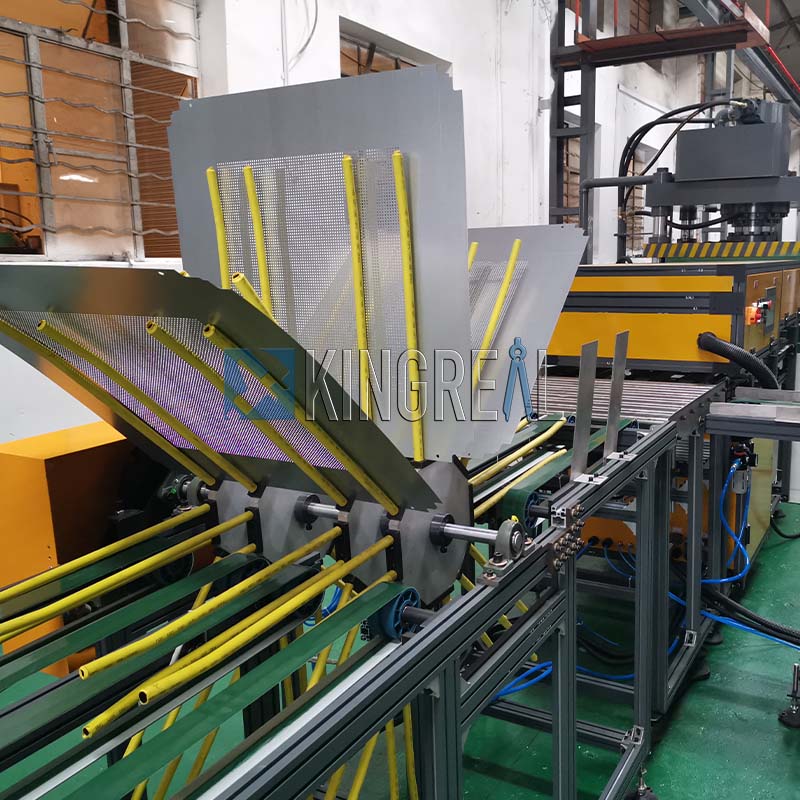

Workflow Automation Reduces Human Intervention

With the support of fully automated ceiling panel production lines, everything from raw material input to finished product output can be achieved seamlessly. This end-to-end automation minimizes reliance on manual labor, boosting production speed while reducing the risk of human error and workplace accidents. For example, the ceiling tile making machines provided by KINGREAL CEILING MACHINERY are capable of handling complex processes without requiring constant supervision, saving manufacturers significant labor costs.

Moreover, automated workflows leverage intelligent scheduling systems to optimize production pacing, reducing idle machine time and maximizing equipment utilization.

How Automation Functions Lead to Efficiency Breakthroughs

The core of automated equipment lies in its ability to enhance efficiency through specific functionalities. Proper utilization of these features can significantly shorten production cycles and streamline manufacturing processes. Here are the key automation features:

High-Speed Operation and Continuous Production

The high-speed operation capabilities of automated ceiling tile machines are a critical means of enhancing efficiency. For example, KINGREAL CEILING MACHINERY's production lines support continuous high-speed production, reducing the time required for each batch of products and meeting the demands of large-volume orders.

The continuous production model also minimizes downtime associated with shifts or machine stops, significantly boosting overall production efficiency. This feature is especially valuable for meeting tight delivery deadlines and seizing market opportunities.

Intelligent Monitoring and Feedback Systems

Intelligent monitoring systems are a standout advantage of automated equipment. The advanced ceiling panel production lines from KINGREAL come with built-in monitoring and feedback functions that can detect the operational status of the machines and the quality of the products in real time. When abnormalities occur, the system can automatically alert operators or adjust parameters to ensure smooth and stable production.

This capability not only enhances production reliability but also minimizes downtime caused by equipment malfunctions, ensuring uninterrupted workflows for 24/7 operations.

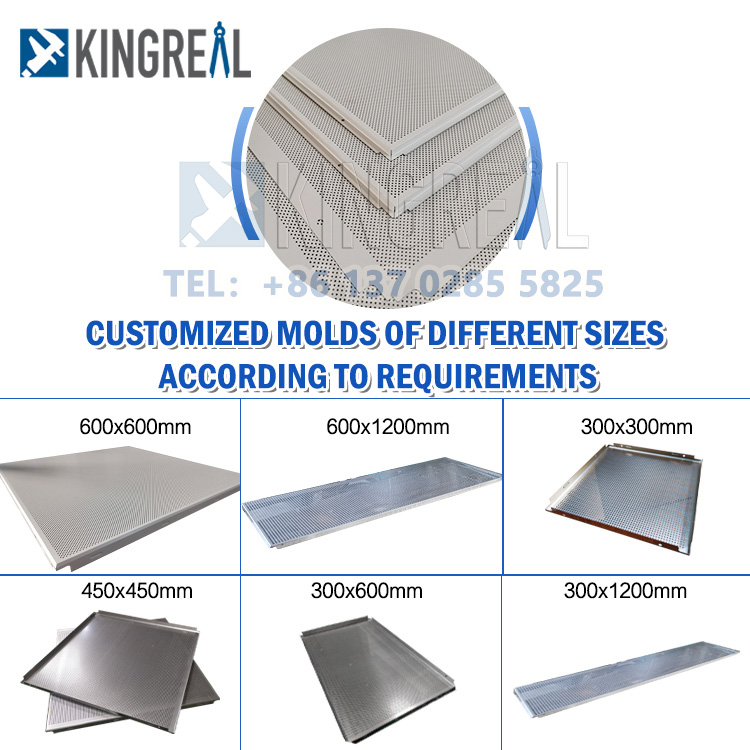

Modular Design for Enhanced Flexibility

KINGREAL CEILING MACHINERY employs modular designs in its ceiling tile making machines, allowing for flexible adjustments based on customer needs. This design not only facilitates upgrades and maintenance but also quickly adapts to changes in market demands. For example, when a manufacturer needs to produce ceiling tiles of different sizes or designs, modular equipment can swiftly modify production parameters to enable efficient transitions.

Such flexibility and adaptability significantly improve a manufacturer's ability to cater to diverse market needs, boosting their competitive edge.

Why KINGREAL CEILING MACHINERY's Automated Ceiling Machines are Widely Trusted?

As a leading company with over 20 years of experience, KINGREAL CEILING MACHINERY is dedicated to providing efficient, precise, and customized solutions for ceiling tile machines and related production equipment.

Advanced Technology and Superior Quality

KINGREAL CEILING MACHINERY's metal ceiling production lines combine state-of-the-art automation technology with precision engineering to meet customers' dual demands for product quality and production efficiency. Whether you're a startup or an established manufacturer, KINGREAL CEILING MACHINERY's machines can help you achieve your production goals and strengthen your market position.

Comprehensive Services with a Customer-First Approach

In addition to high-quality equipment, KINGREAL CEILING MACHINERY offers a full range of support services, including equipment installation, technical training, and maintenance. No matter what challenges customers face, KINGREAL CEILING MACHINERY's team responds promptly to ensure smooth operation of their ceiling tile making machines.

Customization to Meet Individual Needs

KINGREAL CEILING MACHINERY specializes in tailoring solutions based on clients' blueprints and specific requirements. From equipment design to final delivery, KINGREAL CEILING MACHINERY remains focused on customer satisfaction, striving to create greater value for every client.

How to Choose the Right Automated Ceiling Equipment?

When selecting automated equipment, manufacturers need to evaluate multiple factors to ensure the chosen machinery meets both current and future production requirements.

Define Production Needs

Before choosing a ceiling tile machine, manufacturers should clearly define their production objectives, including the types of ceiling tiles to be made, volume requirements, and delivery timelines.

Assess Equipment Performance and Support Services

Equipment performance determines production efficiency, while service quality impacts long-term reliability. The ceiling panel production lines from KINGREAL CEILING MACHINERY have earned widespread praise for their outstanding performance and exceptional service.

Evaluate Cost-Effectiveness

Although high-quality automated equipment requires significant upfront investment, the long-term savings in operational costs and gains in efficiency often result in a higher return on investment.

Conclusion: Automation is the Future of Metal Ceiling Manufacturing

Automation technology has become the key to improving efficiency and competitiveness in the metal ceiling manufacturing industry. From enhancing product quality to optimizing workflows and achieving high-speed production, automated systems offer undeniable advantages. As an industry leader, KINGREAL CEILING MACHINERY provides reliable support through its innovative ceiling tile making machines, metal ceiling production lines, and more.

If you're looking to improve your production efficiency, KINGREAL is your best choice. Contact us today to learn more about our cutting-edge automated solutions and embark on a new era of high-efficiency production!

FAQ

How do continuous production capabilities impact overall efficiency?

Continuous production allows metal ceiling machines to operate without frequent stops or interruptions. This reduces idle time, shortens production cycles, and ensures large orders can be completed faster, meeting tight deadlines effectively.

What types of customer support does KINGREAL CEILING MACHINERY provide for its machines?

KINGREAL CEILING MACHINERY offers comprehensive customer support, including equipment installation, technical training, maintenance, and after-sales service. The company also provides tailored solutions to meet specific manufacturing needs based on client requirements.

How can automation reduce reliance on manual labor in ceiling tile production?

Automation handles complex processes such as material feeding, cutting, perforating, and forming, with minimal human intervention. This reduces errors, lowers labor costs, and enhances safety, making production more efficient and reliable.

Why is precision important in ceiling tile manufacturing?

Precision ensures that ceiling tiles meet exact specifications, reducing defects and enhancing product quality. It also minimizes material waste and supports the production of high-quality products that align with customer expectations.

What factors should manufacturers consider when choosing automated metal ceiling equipment?

Manufacturers should consider their production needs, including tile types and quantities, equipment performance, service support, and cost-effectiveness. Modular designs and adaptability to future demands are also crucial considerations.

Ricevi l'ultimo prezzo? Ti risponderemo al più presto (entro 12 ore)