Come utilizzare una macchina perforatrice per lamiere?

2025-03-10 17:00

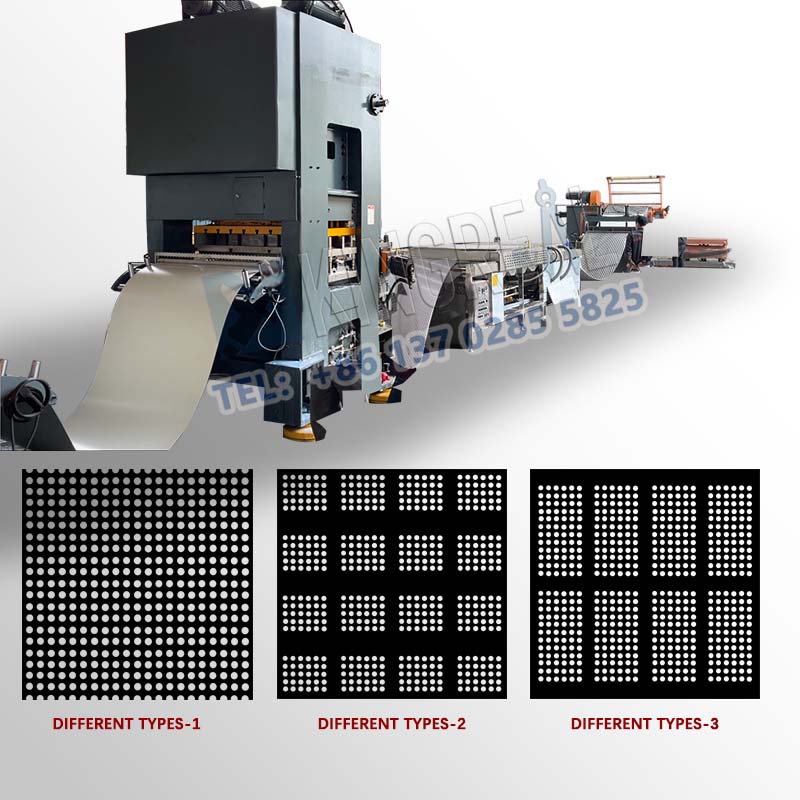

Definition of metal sheet perforation line

A metal sheet perforated machine is a device dedicated to processing metal sheets. By placing the metal sheet into the metal sheet perforation line and using the strong pressure of the punch, the metal perforated making machine can form holes of various shapes and sizes on the metal sheet to produce metal perforated sheets. This metal sheet perforated machine is widely used in many industries and is valued for its efficient production capacity and flexible processing options. |  |

Video About metal sheet perforation line

Uses of metal sheet perforation line

Metal perforated sheets produced by the metal sheet perforation line are widely used in modern industry and construction. Here are some of the main uses:

- Metal perforated making machine in construction industry: Metal perforated sheets are often used in building facades, partitions, ceilings and other decorative materials. They not only have beautiful appearance, but also provide good ventilation and lighting effects.

- Metal perforated making machine in Filtration and ventilation: In water treatment, air filtration and ventilation systems, perforated sheets are used as filters and vents, which can effectively control the flow of fluids.

- Metal sheet perforation line in audio equipment: Perforated sheets are often used in the shell of audio equipment, which can effectively control the propagation of sound and reduce noise.

- Metal sheet perforation line in traffic and transportation: In automotive and aviation manufacturing, metal perforated sheets are used for lightweight design, which can reduce overall weight and improve fuel efficiency.

- Metal sheet perforation line in household goods: In furniture and home decoration, perforated sheets are used as partitions, guardrails and decorative panels, which increase the beauty and practicality of the products.

- Metal perforated making machine in electronic equipment: In electronic products, perforated sheets are used for heat dissipation and protection, which can effectively improve the performance and service life of the equipment.

Ways of using metal perforated making machine

The process of using the metal perforated making machine is relatively simple, but certain steps need to be followed to ensure the efficiency and quality of the processing. The following are the basic methods of using the metal sheet perforation line:

1/ Decoiler for metal sheet perforation line

Before the processing begins, the metal coil needs to be placed on the decoiler of the metal sheet perforated machine. The uncoiling process includes the following steps:

- Placing the coil: Place the metal coil on the base of the decoiler to ensure that the coil is firmly fixed in place.

- Adjust the tension: According to the thickness and type of the coil, adjust the tension of the decoiler to ensure that the coil will not be twisted or deformed during subsequent processing.

- Determine the material width: According to the specifications of the metal perforated making machine, ensure that the width of the metal coil is suitable for the subsequent leveling and punching operations.

2/ Leveling machine for metal sheet perforation line

The metal coil after unwinding usually has a certain bend or wave shape, which needs to be leveled by the leveling machine. The purpose of leveling is to ensure that the metal sheet can withstand pressure evenly during the punching process and avoid unnecessary deformation. The leveling process includes:

- Feeding: Feed the metal sheet into the leveling machine to ensure that it fully enters the leveling area.

- Adjust the leveling machine: According to the thickness of the metal sheet and the type of material, adjust the pressure and gap of the leveling machine to achieve the best leveling effect.

- Check the flatness: After the leveling is completed, check the flatness of the metal sheet to ensure that there are no obvious waves or bends.

3/ Punching machine for metal sheet perforation line

Punching is the core processing step of the metal sheet perforation line. In this stage, the metal sheet will pass through the metal perforated making machine and form the predetermined holes through the action of the punch. The specific steps are as follows:

- Set punching parameters: According to the design requirements, set the parameters of the metal sheet perforation line, including hole diameter, hole spacing and punching speed. The setting of these parameters directly affects the quality and efficiency of punching.

- Feeding: Feed the flattened metal sheet into the metal perforated making machine to ensure that it is in the correct position and aligned with the punching head.

- Start the metal sheet perforated machine: Start the metal sheet perforation line, and the punch will punch the metal sheet at the set speed and pressure. Pay attention to the punching process to ensure that no abnormalities occur.

- Monitor quality: During the punching process, regularly check the punching quality to ensure that the size and shape of each hole meet the design requirements.

4/ Recoiler for metal perforated making machine

After punching, the metal sheet can be rewound as needed:

- Rewinding: If the punched sheet is long and does not need to be cut, you can choose to rewind it. The recoiler rolls the punched metal sheet into a roll for subsequent storage and transportation.

Precautions for using the metal perforated making machine

When using the metal sheet perforated machine, there are some important precautions to follow to ensure the safety of operation and processing quality:

1. Safe operation

- Wear personal protective equipment: When operating the metal perforated making machine, be sure to wear appropriate protective equipment, including safety glasses, gloves and earplugs, to ensure your own safety.

- Familiarità con il funzionamento dell'attrezzatura: prima di utilizzare la linea di perforazione della lamiera, l'operatore deve avere familiarità con il manuale operativo dell'attrezzatura e comprendere le funzioni e le procedure operative sicure di ciascun componente.

- Garantire il normale funzionamento dell'attrezzatura: prima di iniziare la produzione, controllare tutte le parti dell'attrezzatura per assicurarsi che non vi siano parti danneggiate o allentate.

2. Selezione del materiale

- Selezionare materiali metallici adatti: in base ai requisiti di punzonatura e alle aree di applicazione, selezionare materiali metallici adatti come acciaio inossidabile, lega di alluminio, ecc. per garantire la resistenza e la durata dei materiali.

- Controllare la qualità dei materiali: prima di iniziare la lavorazione, controllare la qualità della bobina di metallo per assicurarsi che non vi siano difetti o danni evidenti, per evitare di compromettere la qualità della punzonatura.

3. Manutenzione regolare

- Controllare regolarmente l'attrezzatura: effettuare regolarmente la manutenzione e l'ispezione della macchina per la produzione di fori in metallo per garantire il normale funzionamento di ogni componente e sostituire tempestivamente le parti danneggiate.

- Lubrificazione e manutenzione: Lubrificare regolarmente l'attrezzatura per ridurne l'usura e prolungarne la durata utile.

4. Monitorare il processo di produzione

- Monitoraggio in tempo reale: durante il processo di punzonatura, l'operatore deve mantenere un monitoraggio in tempo reale del processo produttivo per garantire la qualità della punzonatura.

- Regolare i parametri in tempo: in base alla situazione di produzione effettiva, regolare in tempo i parametri della linea di perforazione della lamiera per garantire l'efficienza della produzione e la qualità del prodotto.

Ricevi l'ultimo prezzo? Ti risponderemo al più presto (entro 12 ore)