Che cosa sono i controsoffitti in alluminio?

2024-11-12 11:55

Video About U baffle machine

Aluminum baffle ceiling, also known as aluminum channel ceiling, has become one of the more common ceiling materials in recent years. Its transparency, strong decorative effect, and high fire resistance have made it increasingly popular for concealed projects and high-traffic public spaces. It is also an indispensable part of many home renovations.

Among them, the metal baffle ceiling is produced by the baffle ceiling roll forming machine to flatten, shape, and cut the metal raw materials. This article will provide a detailed introduction to more information related to aluminum baffle ceilings.

Definition of U Baffle Machine

An aluminum baffle ceiling is a ceiling made from aluminum baffle materials, which are also known as U-shaped baffles or U-shaped channels.

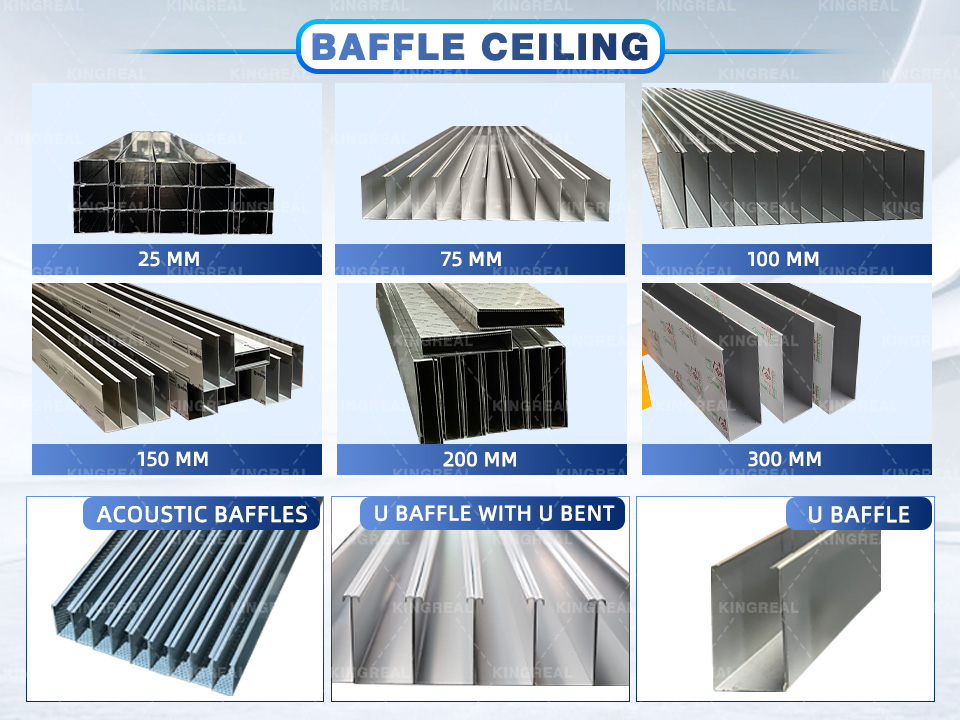

Common Types

Aluminum baffle ceilings can be categorized based on different surface treatments, baffle shapes, and material processes.

By Surface Treatment: It can be divided into fluorocarbon paint, polyester paint, wood grain heat transfer, powder, stone grain, real stone paint, anodizing, and so on.

By Baffle Shape: It can be divided into straight bars, arcs, special-shaped and so on.

By Material Process: It can be mainly divided into aluminum plate aluminum square and aluminum profile square.

Common Parameters

Taking u-shaped aluminum baffle ceiling as an example, common parameters include:

• Base Width: 20mm to 150mm, with increments of 5mm between each width.

• Side Height: 30mm to 180mm, with increments of 5mm between each height.

• Thickness: 0.5mm to 1.0mm.

• Length: Typically, lengths of 1 to 3 meters are ideal, and lengths within 6 meters can be customized.

• Colors: Generally available in solid colors and wood grain colors, with options for custom colors.

(The above parameters are common for most products on the market and are for reference only.)

Advantages of Baffle Ceiling Machine

U baffle machine's features:

(1) Lightweight and Durable: Made from aluminum, metal baffle ceilings are lightweight yet strong and durable, resistant to deformation or damage.

(2) Fire Resistance: They have excellent fire resistance, helping to prevent the spread of fires and ensuring safety for people and property.

(3) Easy Installation and Maintenance: Metal baffle ceilings are installed using a modular system, making installation quick and easy, with convenient maintenance and replacement of damaged parts.

(4) Corrosion Resistance: They are highly resistant to corrosion, not easily affected by moisture, rust, or chemical corrosion, making them suitable for humid or chemically aggressive environments.

(5) Aesthetic Appeal: The smooth, flat surface and simple lines of aluminum baffle ceilings offer a modern look that enhances interior decoration.

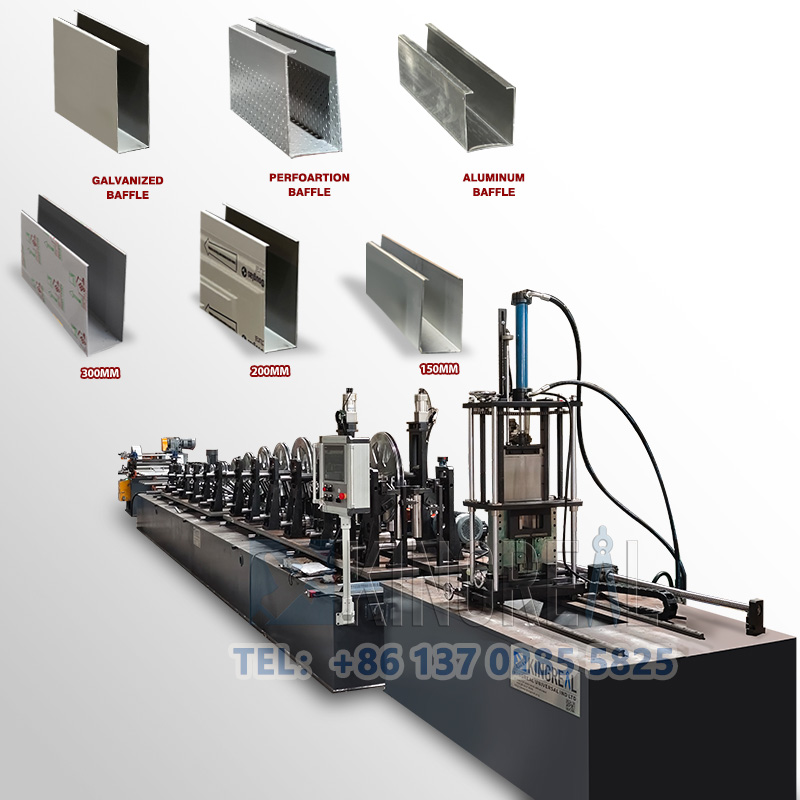

What does KINGREAL CEILING MACHINERY Baffle Ceiling Machine Offer?

1. To meet the production needs of different sizes of baffle ceiling, the u baffle machine can automatically adjust the width to produce different sizes of u baffle ceilings, you do not need to change the machine frequently to produce different sizes of baffle ceiling machines.

2. Customized solution. The 300mm height baffle ceiling machine is customized according to the actual production needs of customer Douglas, KINGREAL CEILING MACHINERY can meet the special needs of customers for u baffle production size. If you have new ideas and needs for baffle production, welcome to send your drawings to KINGREAL CEILING MACHINERY. KINGREAL CEILING MACHINERY designers will customize your baffle ceiling roll forming machine after full communication with you.

3. More efficient production. KINGREAL CEILING MACHINERY baffle ceiling production line uses follow cutting, you only need to enter the required cutting parameters, the system can detect the length of baffle material through the sensor, and control the tool at the right time to cut. The follow cutting can improve cutting efficiency and accuracy, reduce downtime and waste, and greatly improve your productivity.

Various baffle ceiling machines

In modern architecture and interior decoration, baffle ceilings are widely favored for their elegant appearance and excellent functionality. In order to meet customers' different production needs for baffle ceilings, KINGREAL CEILING MACHINERY has launched various types of baffle ceiling making machines with flexible production capacity and diverse design options. The following is a detailed introduction to different types of baffle ceiling machines.

1. Height-adjustable baffle ceiling machine

KINGREAL CEILING MACHINERY's baffle ceiling machine series includes a variety of models with different heights, mainly the following:

150mm height baffle ceiling machine

This model is designed for the production of baffle ceilings with a maximum height of 150mm. This baffle ceiling machine can quickly respond to market demand with its efficient production capacity and precise molding technology.

200mm height baffle ceiling machine

The 200mm baffle ceiling machine can produce baffle ceilings with a maximum height of 200mm. It maintains stable performance during the production process to ensure that the size and shape of each baffle ceiling meet the design requirements.

300mm height baffle ceiling machine

The 300mm baffle ceiling machine is designed according to the special needs of Douglas, a KINGREAL CEILING MACHINERY customer, and is capable of producing baffle ceilings with a maximum height of 300mm. This model is particularly suitable for projects that require large-sized baffle ceilings, providing greater design flexibility and meeting the needs of high-specification ceilings.

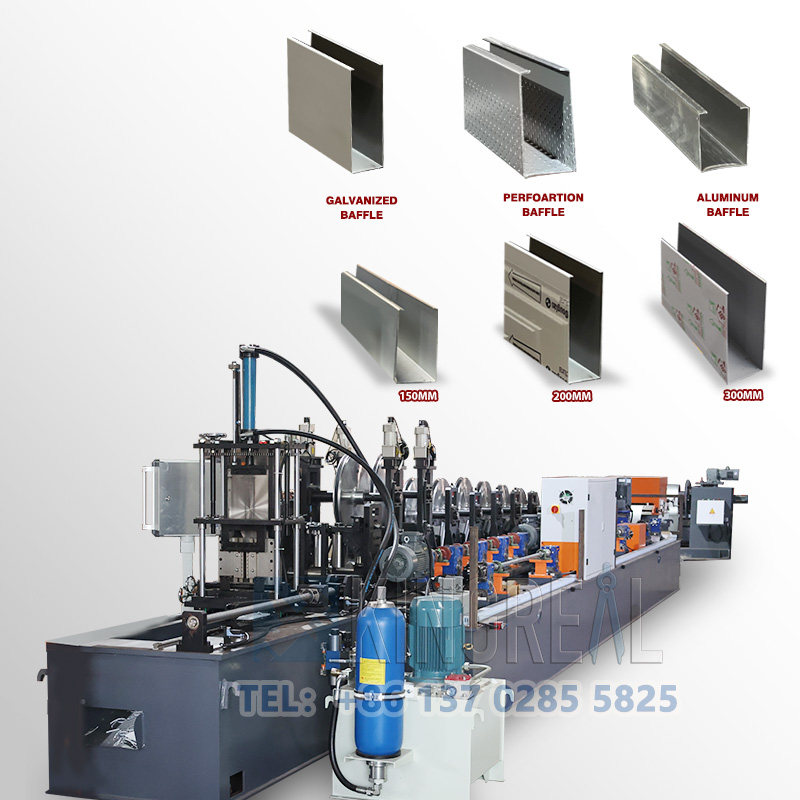

2. Special baffle ceiling machine according to different types

KINGREAL CEILING MACHINERY has also launched a variety of baffle ceiling machines based on different types of baffle ceilings, including:

U-shaped baffle ceiling machine

La macchina per controsoffitti a baffle a forma di U è dedicata alla produzione di controsoffitti a baffle a forma di U, adatti a vari stili di decorazione d'interni. Il suo design consente la produzione di una struttura unica a forma di U, che aumenta la stratificazione e l'effetto visivo del controsoffitto ed è ampiamente utilizzata in spazi commerciali e progetti residenziali.

Macchina per soffitto a baffle a forma di V

La macchina per controsoffitti a baffle a V viene utilizzata per produrre controsoffitti a baffle a V, offrendo un'opzione estetica diversa dai controsoffitti a baffle tradizionali. Il design a V non è solo bello, ma migliora anche l'effetto di riflessione della luce, aggiungendo un tocco di luminosità all'ambiente interno.

Macchina per soffitto a baffle a forma di U con piega a U

Questa macchina è progettata appositamente per la produzione di controsoffitti a baffle a forma di U con piega a U. Il design pieghevole rende il controsoffitto a baffle più stabile durante l'installazione e migliora l'estetica generale. È adatta per progetti con elevati requisiti di estetica e funzionalità.

Conclusione

Grazie alla sua estetica superiore, alla sua durevolezza e funzionalità, il controsoffitto a baffle in alluminio è stato ampiamente utilizzato in vari progetti di costruzione, tra cui spazi commerciali, strutture pubbliche, case intelligenti e campi di edilizia verde. Con il continuo sviluppo della tecnologia, anche la progettazione e il processo di produzione del controsoffitto a baffle in alluminio sono costantemente innovativi per soddisfare le esigenze di mercato sempre più diversificate. Che si tratti di migliorare l'effetto visivo dello spazio, di garantire la sicurezza o in termini di protezione ambientale ed efficienza energetica, il controsoffitto a baffle in alluminio ha mostrato i suoi vantaggi unici.

Nella produzione di controsoffitti in alluminio, è molto importante scegliere attrezzature di produzione efficienti e precise. KINGREAL Ceiling Machinery, con i suoi avanzati sistemi automatizzatimacchine per la formatura a rulli del soffitto a traliccio, fornisce soluzioni flessibili, precise ed efficienti per soddisfare esigenze di produzione di diverse dimensioni e specifiche, aiutando i clienti ad aumentare l'efficienza produttiva, ridurre gli sprechi e migliorare la qualità del prodotto. Che si tratti di un grande progetto commerciale o di un miglioramento domestico personalizzato, le attrezzature KINGREAL CEILING MACHINERY possono fornire il supporto perfetto ai clienti per garantire l'alta qualità dei prodotti e l'efficienza produttiva.

Con il continuo sviluppo del mercato, i controsoffitti in alluminio mostreranno il loro potenziale in più aree e KINGREAL CEILING MACHINERY continuerà a impegnarsi a fornire ai clienti tecnologie di produzione innovative e servizi di qualità per favorire lo sviluppo a lungo termine del settore.

Ricevi l'ultimo prezzo? Ti risponderemo al più presto (entro 12 ore)